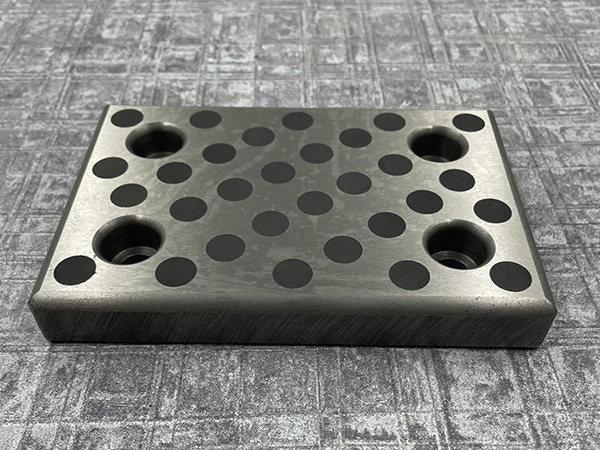

Spring positioning pin

Description: The spring positioning pin is mainly designed to cushion vibration and impact. The elastic positioning pin is designed with the concept of a spiral spring. The elasticity of the spring positioning pin allows it to be pressed into the hole and still mainta

Mobile:+86 18333769655 +86 15630734447

Email:zhanghemoju@163.com

Product Description:

The Spring positioning pin is mainly designed to cushion vibration and impact. The elastic positioning pin is designed with the concept of a spiral spring. The elasticity of the Spring positioning pin allows it to be pressed into the hole and still maintain elasticity after being installed in the hole. If there is no elasticity, the load on the pin will be transmitted around the hole. Usually, due to the softness of the hole compared to the pin, it will cause the hole to stretch or expand, and the fit between the hole and the pin will become loose, increasing the probability of impact and hole failure. The inevitable result is premature failure of the component.

If applied properly, the elasticity of the Spring positioning pin can play a buffering role in vibration and impact, thus avoiding damage to the holes on the components and greatly extending the product life cycle. The uniform strength and direction of elastic force will not affect the elastic and shear strength of the Spring positioning pin. The pin contracts from the outer ring to the inner ring. When pressure is applied to the pin and released, such as being subjected to vibration or impact, the pin contracts and extends synchronously. Excessive load will cause the pin to shrink into a solid shape, and further stress will lead to shear failure. Under the correct application, this situation should not occur.

The stress transmitted to the pin during the assembly process, as well as the applied loads, vibrations, and impact forces, are evenly distributed throughout the entire Spring positioning pin. This characteristic is interrelated with the strength and uniformity of elasticity of the pin, and is an inherent characteristic of coil spring design. The concentration of stress can cause a particular point to be particularly fragile, leading to premature fatigue failure of the component. There will be no stress concentration at a certain point in the Spring positioning pin. The elasticity, strength, diameter of the spring positioning pin rolled with the type of load need to be appropriately combined with the corresponding component materials to achieve optimal performance of the pin. The strength and elasticity of the pin need to be balanced against each other.

If the strength of the pin is too strong after applying the load, it cannot shrink and will cause hole damage. If the strength of the pin is insufficient, it will shrink excessively and cause failure. The strength and elasticity should be balanced, the diameter should be appropriate, and the applied load can be transmitted without damaging the hole wall. That's why Spring positioning pins provide different types of loads. The purpose is to achieve a balance of strength, elasticity, and diameter to accommodate different pore materials.